Prefiltration

system

An Introduction to Prefiltration

Prefiltration plays an indispensable role in both chemical recovery processes, such as anodizing and steel pickling, and advanced filtration methods, such as nanofiltration. In the field of chemical recovery, prefiltration helps safeguard the integrity and efficiency of the process by eliminating larger impurities from the chemical mixtures, thus preventing potential damage to sensitive recovery equipment and enhancing the overall efficacy of the operation.

In advanced filtration methods like nanofiltration, prefiltration proves essential in prolonging the life of the finer membranes, reducing system downtime due to fouling or clogging, and improving overall filtration performance.

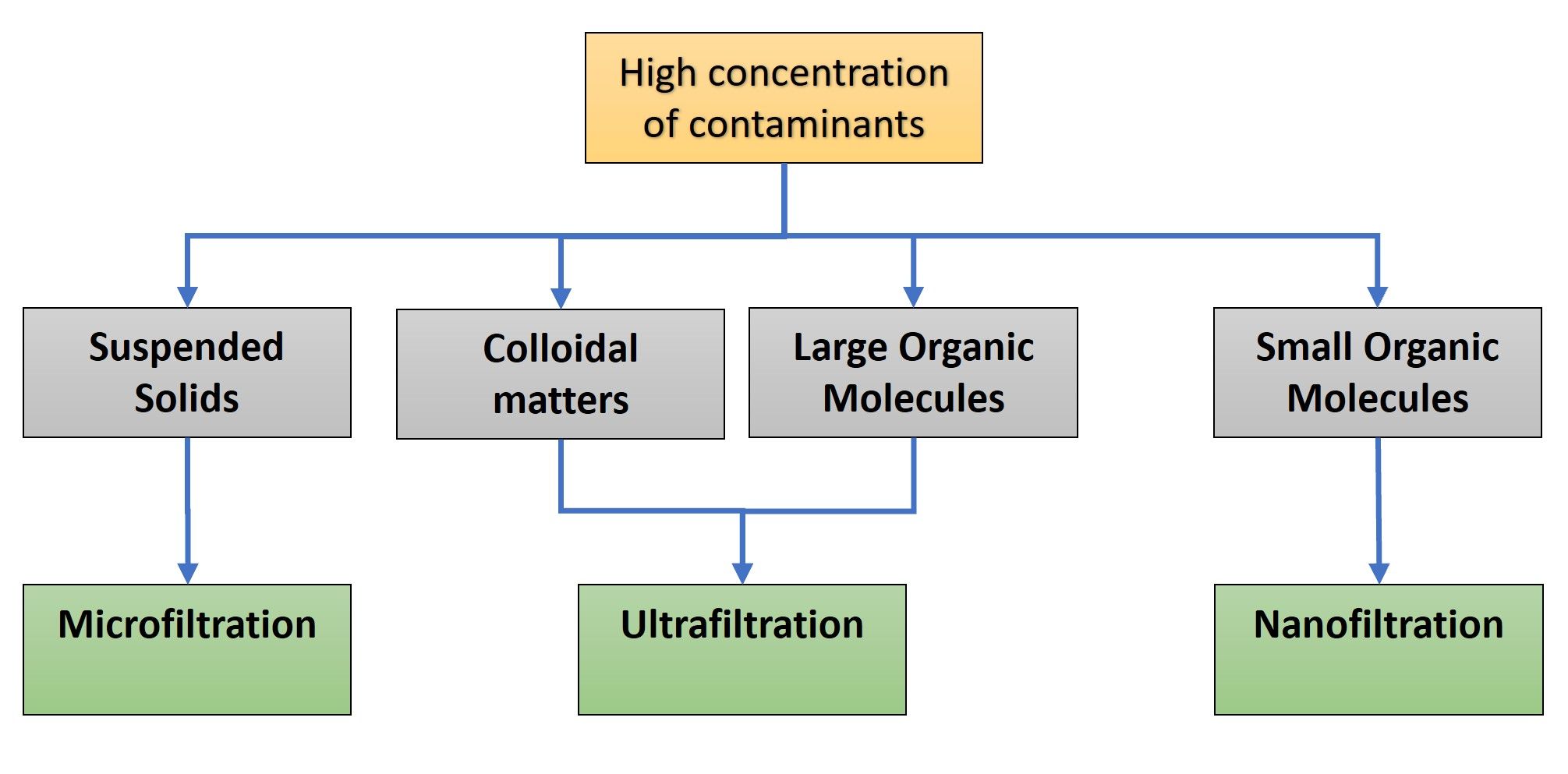

By applying prefiltration techniques, such as microfiltration (MF) and ultrafiltration (UF), industries can ensure the preservation of sensitive stages, reduce operational costs, and enhance the quality and consistency of the final output.

Advantages of prefiltration at Spiraltec GmbH

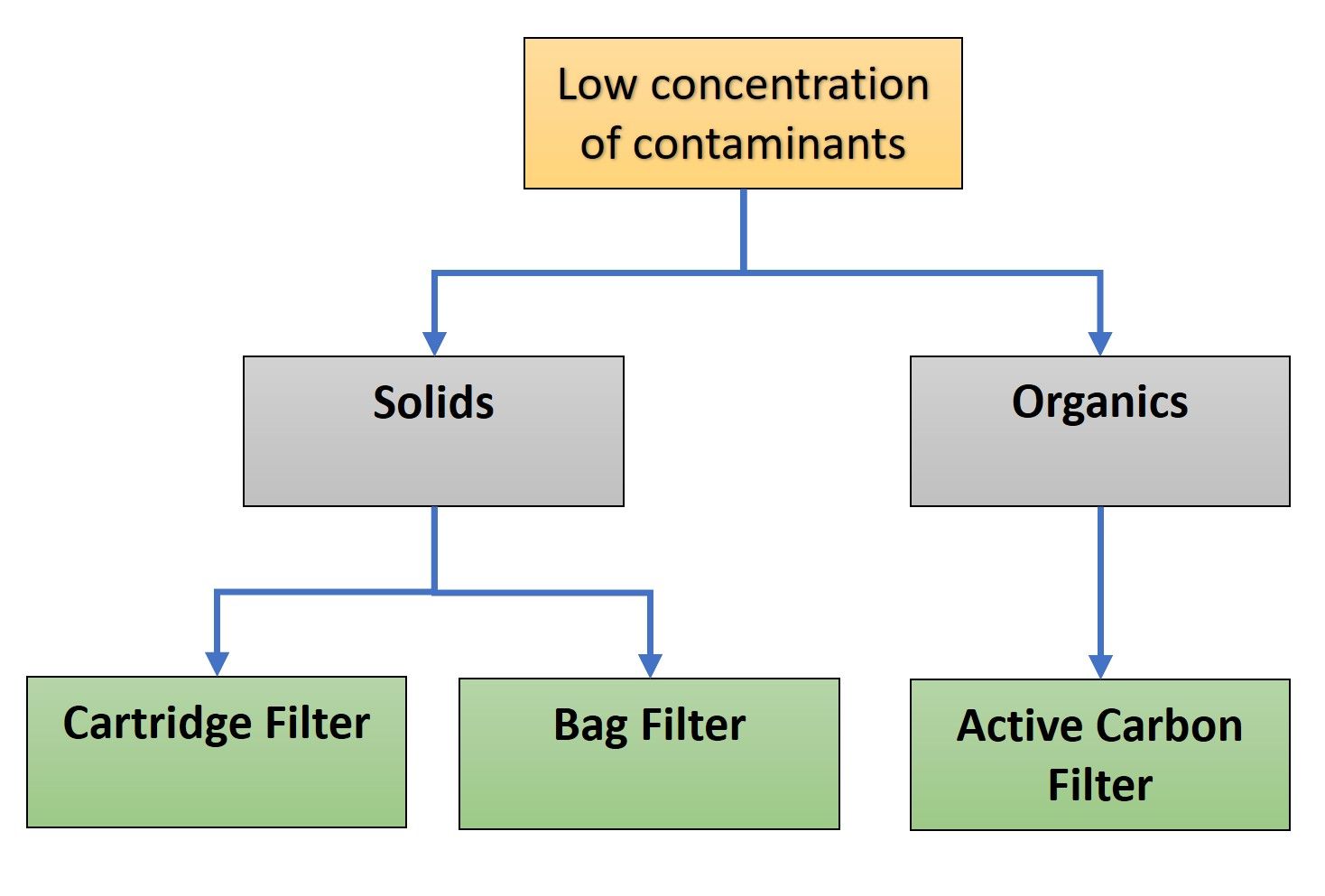

Types of Contaminants in Wastewater Addressed by our Prefiltration System

Particulate Matter

Microorganisms

Debris

Oils and Fats

Large Inorganic Compounds

Large Organic Compounds

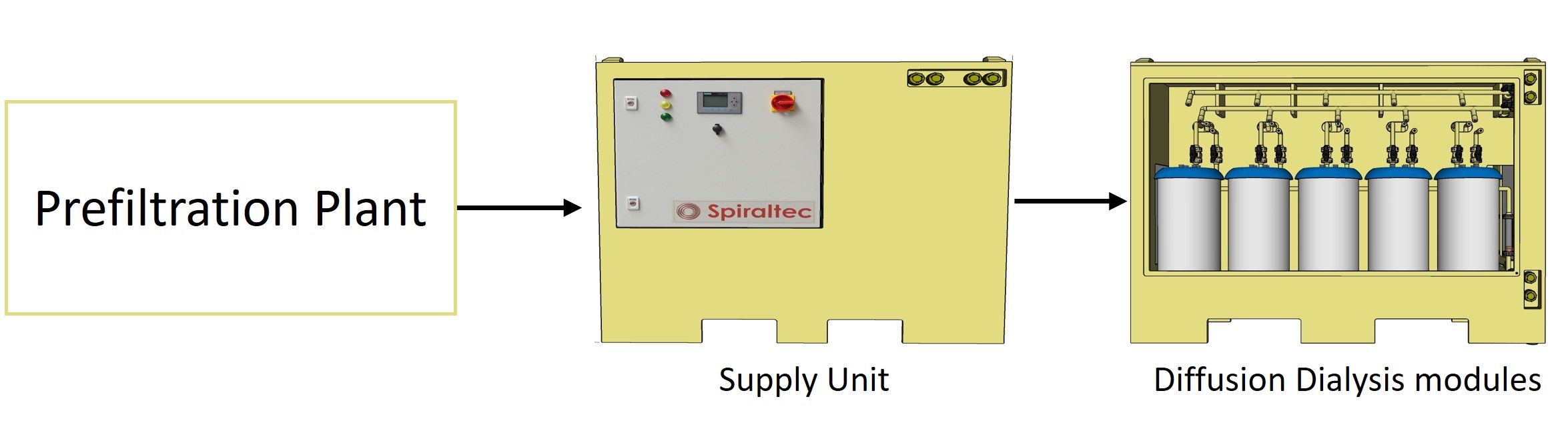

Prefiltration for diffusion dialysis for the recovery of acids or bases

Application of Prefiltration in Chemical Recovery process Through Diffusion Dialysis Technology

In the context of chemical recovery, prefiltration is employed to ensure the longevity and efficiency of the recovery process.

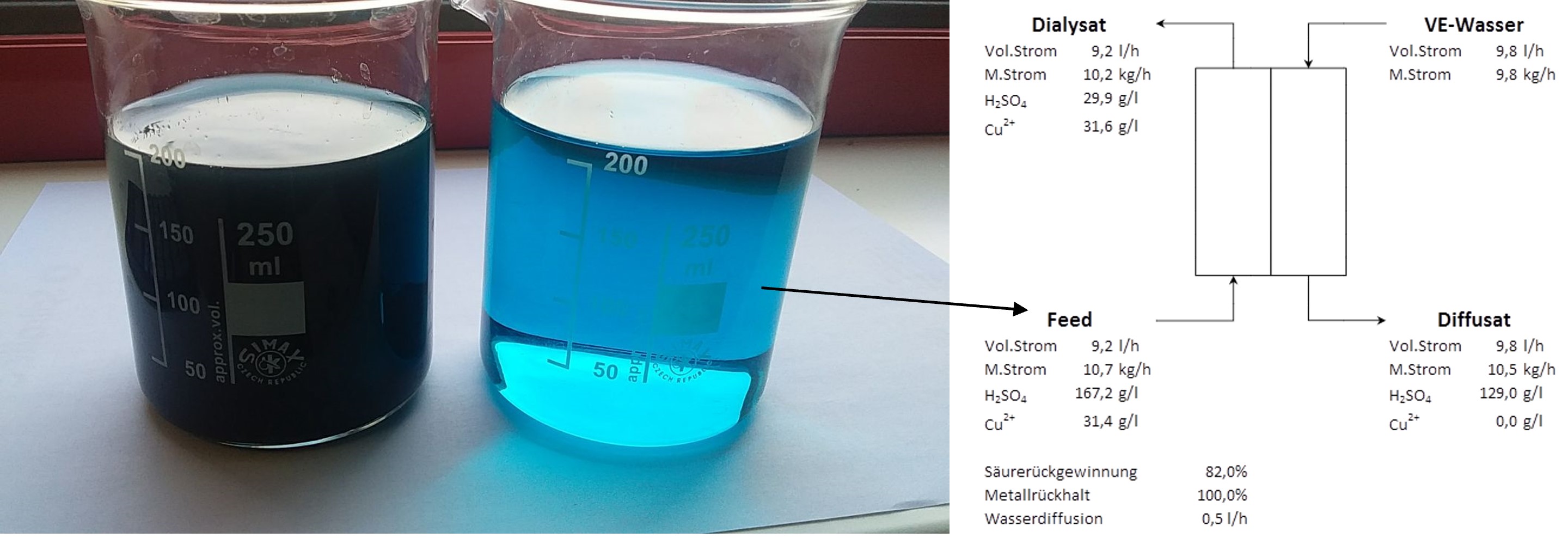

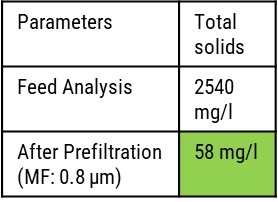

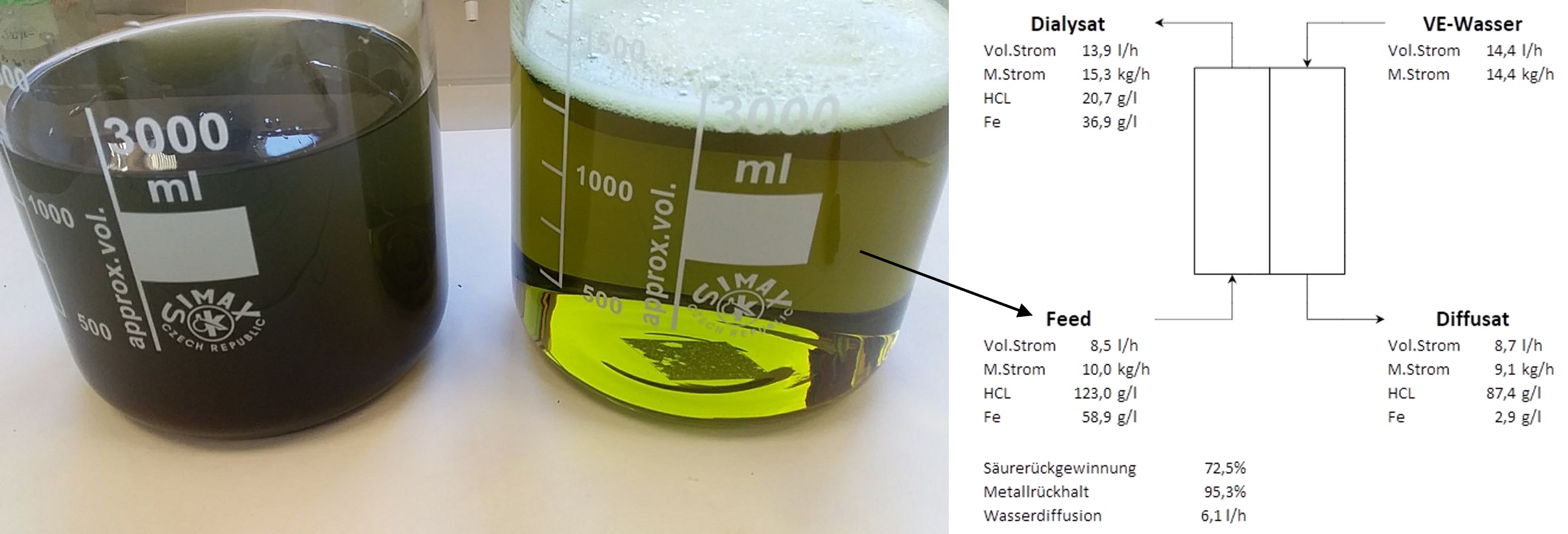

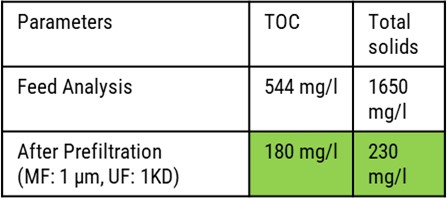

Industrial processes often produce complex mixtures of chemicals, some of which are valuable and need to be recovered. In this case, the recovery of H2SO4 from Anodizing industry or HCl from steel pickling can be mentioned as example.

Prefiltration aids in separating larger impurities from these mixtures, preparing them for further precise separation techniques. This step can reduce the burden on downstream processes (e.g Diffusion dialysis), prevent potential damage to sensitive equipment, and increase the overall efficiency and effectiveness of the recovery operation.

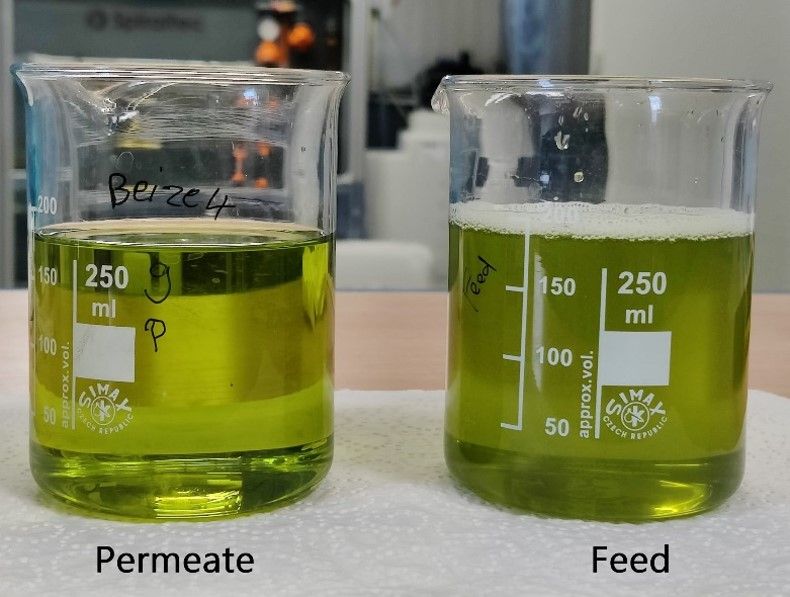

Example: pilot test

In our effort to enhance unit design, we use our multifunction prefiltration pilot test to obtain key parameters

- Selection of appropriate membrane material (ceramic or polymer)

- Precise determination of membrane pore size (MF: 1.2 - 0.1 µm; UF: 0.05 μm - 500 Dalton).

- Evaluation of COD, TOC, TSS, etc. removal efficacy.

- Estimation of membrane permeability based on the solution type.

- Determination of operation mode (cross-flow or dead-end).

- Backwash duration estimation.

- Estimation required backwash time.

- Determining the optimal operating pressure.

The system is also stable for pH range 0 - 14

Sample Examples:

Results of H2SO4 Recovery Using Diffusion Dialysis Modules Following Prefiltration

Results of HCl Recovery Using Diffusion Dialysis Modules Following Prefiltration

We will be glad to help you!

Ongoing research for new areas of application.